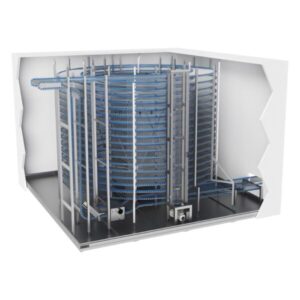

TECNOPOOL PROGETTA Spirali di Surgagezione per prodotti da forni e dolciari, meat e pesce, pasta, frutta and vegetables and piatti prompt. Ogni Imistanto di Surgagezione è Progetato E Studiato per soddisfare le specifiche esigenze of the client, guarantando il rispetto degli eleati standard di sicurezza food per il treatment di cibi confezionati or sfusi . P>

La Spirale, Grazie Alla Sua Struttura depriva di qualsiasi Ostacolo Centraloe, permete a Facile Pulizia and Manutenzione in Ogni sua part . Tale configures consequent inoltre l & rsquo; ottimizzazione of the flusso d & rsquo; Aria Orizzale che comes channeling ed investe in manera uniform ed efficacece tutti i prodotti all & rsquo; internal of the cella cella di surgelaz. EFFICIENZA DEGLI evaporatori , dimensionati in base alla typology of prodotti da tattare, riducone novolmente and consumer energetici dell & rsquo; imparto, rendering it più sustainibile dal point of the economic /P>

Eurotecsa® es una marca registrada por Grupo Crest S.A.de C.V.

Todos los derechos reservados.

Copyright 2023.

2023 Todos los derechos Reservados Eurotecsa Grupo Crest | Soluciones Integrales de Alta Tecnología al Servicio de la Industria